Ich habe selbst kein Master Hunter, aber zum Stahl kann ich was beitragen. Mehrere Messer aus 80CrV2 (2 Winkler und Terävä Skrama sowie Puukko) und CPM 3V (diverse Bark River, Jeremy Robertson) haben sich bei mir auf das erfreulichste bewährt. Selbst bei relativ filigraner Geometrie (BRKT Kephart) hält der CPM 3V auch anspruchsvoller Nutzung ohne Chipping stand.

Ganz grundsätzlich würde ich die Toughness (Zähigkeit) etwa gleich einschätzen. Der CPM 3V bleibt allerdings länger scharf, was schon an der Zusammensetzung deutlich wird:

80CrV2: C: 0,8 Cr: 0,5 Mn: 0,4 Si: 0,25 V: 0,2

CPM 3V: C: 0,80 Cr: 7,50 Mo: 1,30 Mn: 0,40 Si: 0,90 V: 2,75-3,00 W: 0,40 max

Die Chrom- und Vanadium-Karbide im CPM 3V stehen für Edge Retention. Er schärft sich allerdings auch nicht so leicht wie 80CRV2. Solange die Klinge nur nachzuschärfen ist, gelingt das aber schon durch Stroppen auf Schleifleinen. Größere Sachen erfordern etwas mehr Mühe. Shapton Glasstones haben kein Problem. Aber auch grobes Schleifpapier geht.

Hier einige

Einschätzungen von amerikanischen Messermachern und David Winkler:

„The toughness is similar (very high), due to similar structure (which is due to the same basic chemistry). 3V will have significantly better wear-resistance and corrosion-resistance, from much higher amounts of chrome, vanadium and moly. For people that don't mind sharpening a little more often, and don't care much about a little staining, 80CRV2 is absolutely comparable to 3V... the upshot is they can both make very tough knives that perform very well.

It's reasonable to describe it as 1080 < 1084 < 80CRV2 < CPM-3V in all pertinent areas. Again, the only real difference is increasing amounts of alloying elements.“

„I ever had a conversation to

Daniel Winkler about 80CRV2 and CPM3V which both are his current use steel.

He said that both are very comparable in edge retention but 80CRV2 will be easier to sharpen while 3V has the edge on lateral strength and corrosion resistance.“

UND:

80CRV2 Spring Steel- This is a German spring steel that has gained a reputation for being tough as nails with good edge retention. The simplest way to explain its performance is 5160 toughness with 1095 to O1 edge retention. I heat treat this steel to a 60-61RC for a good balance of performance. Easy to sharpen, holds a good edge and with toughness that won't let you down its hard not to like this steel! At the moment due too the limited suppliers of 80CRV2 in the US I do not take custom orders for it at this moment. It will need to be cared for to prevent rust.

CPM 3V Tool Steel- This is one of the toughest tool steels suitable for use as a knife. With large amounts of Chromium and Vanadium this steel is extremely tough and holds an edge for a very long time. It also has some rust resistance although it is still a carbon steel and will need care. The largest downside to 3V is it is very hard to sharpen, especially in the field. Without diamond or ceramic based sharpeners you will not be able to sharpen this steel to a good edge. You'll also notice that it just doesn't get quite as sharp as the simpler carbon steel like O1 and 80CRV2, so if a razor edge is your cup of tea this may not be your steel. I have this steel heat treated by Peters Heat Treating to a 60RC.

Zur Härte des Master Hunter habe ich noch folgendes gefunden:

59 HRC

Die Frage ist jetzt natürlich, ob diese Angabe auch verläßlich ist

und dann, wie es um die Wärmebehandlung bei Cold Steel bestellt ist.

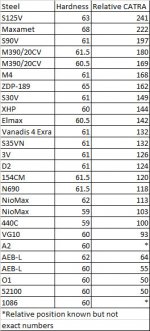

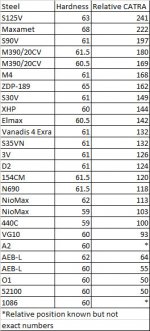

Was die relative Schnitthaltigkeit von CPM 3V angeht, hier noch eine kleine Tabelle von Larrin Thomas (Knifesteelnerds):

CPM 3V bewegt sich bezüglich seiner Schnitthaltigkeit bei vergleichbarer Härte auf dem Niveau von D2 und S35VN.

R’n‘R